Tracks & Rail traffic

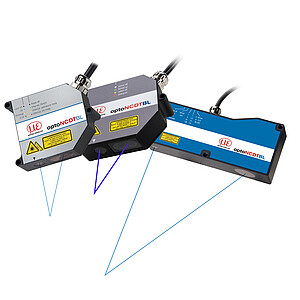

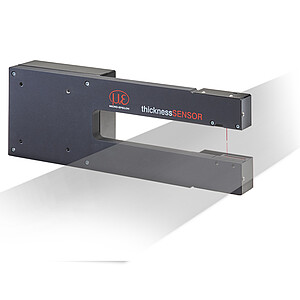

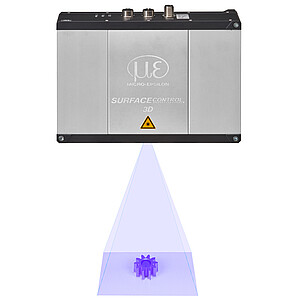

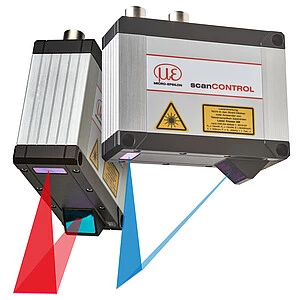

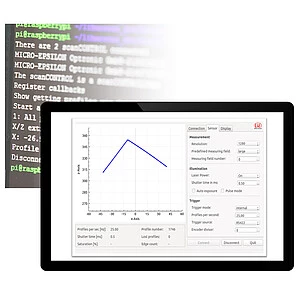

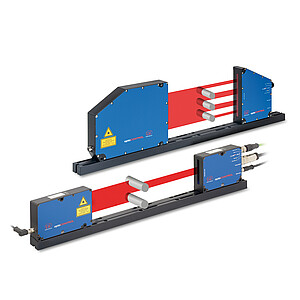

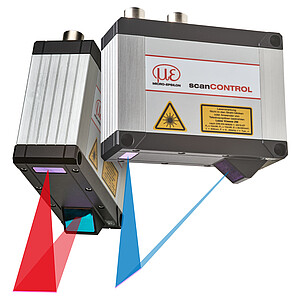

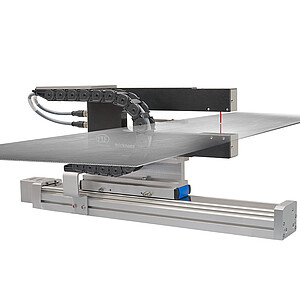

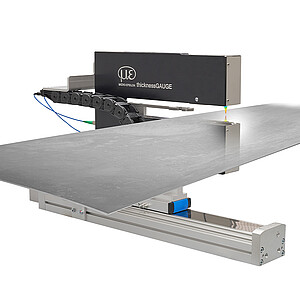

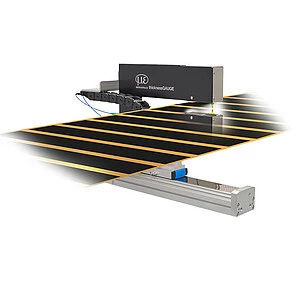

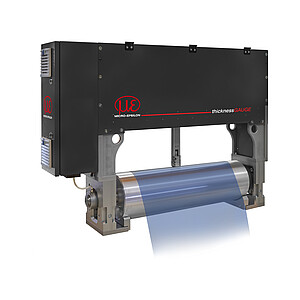

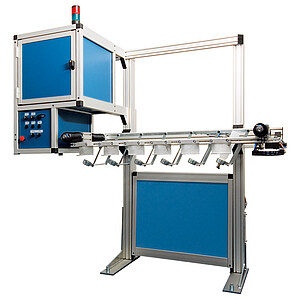

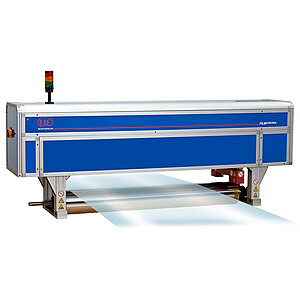

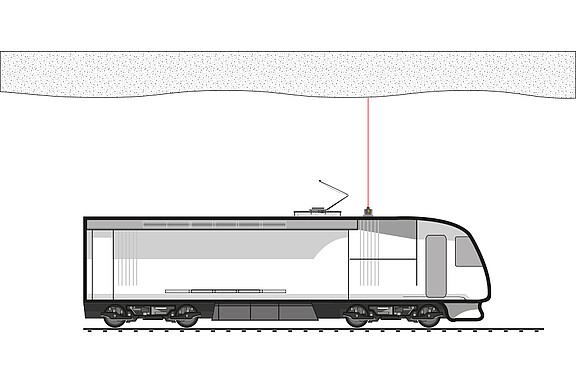

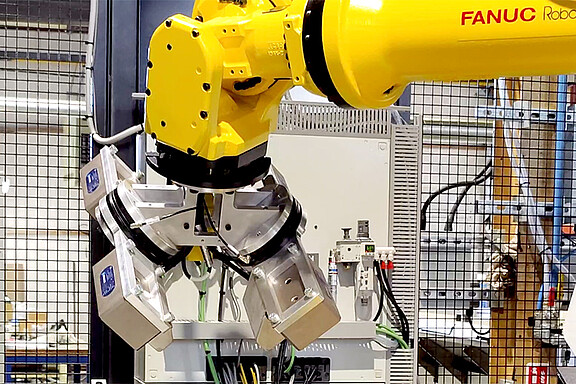

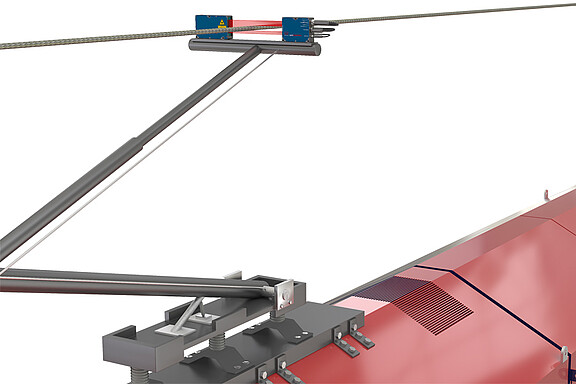

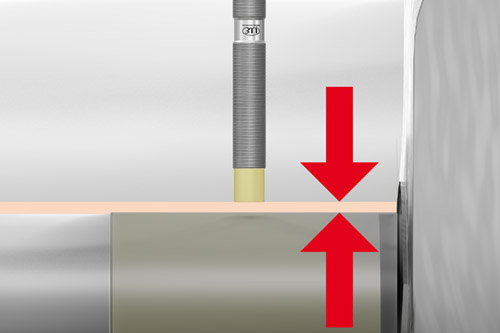

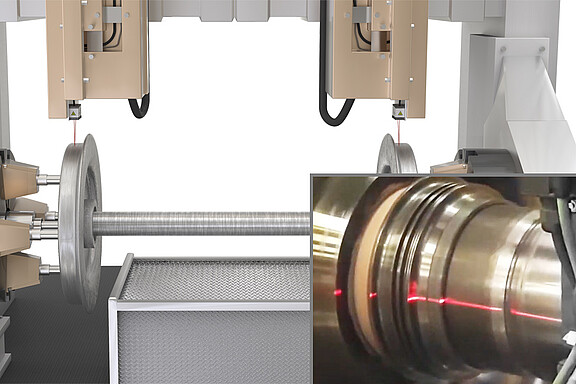

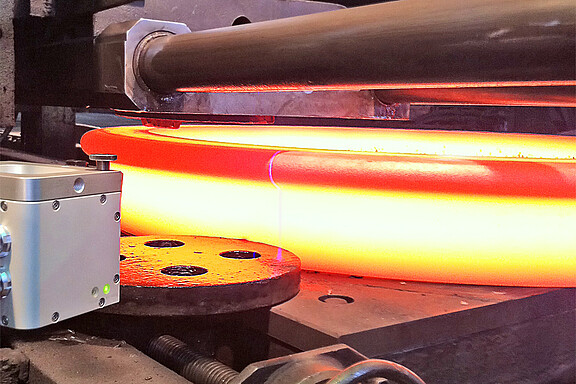

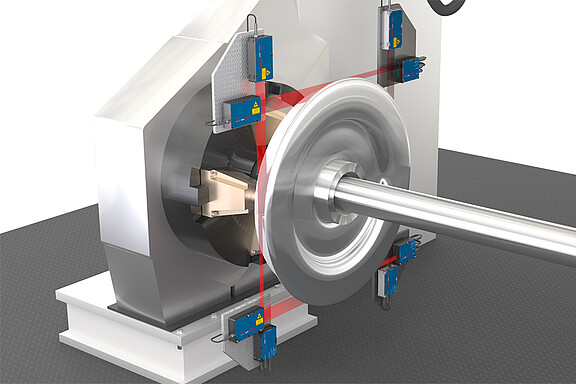

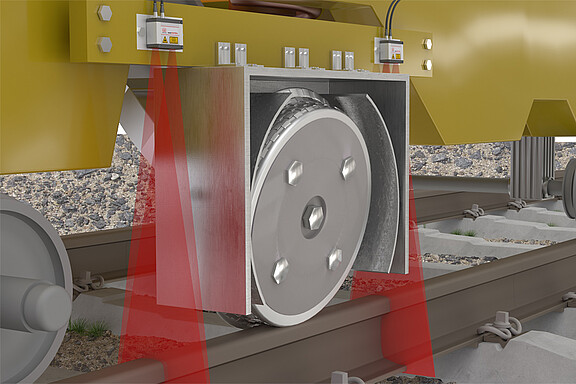

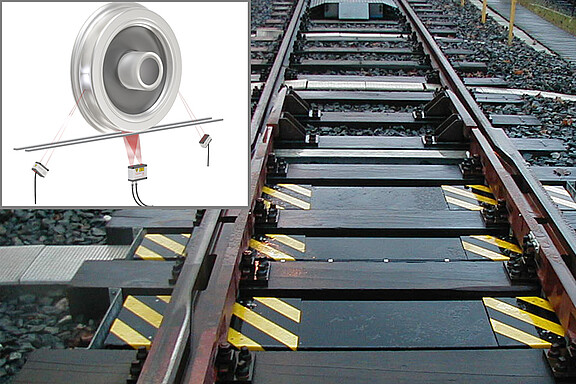

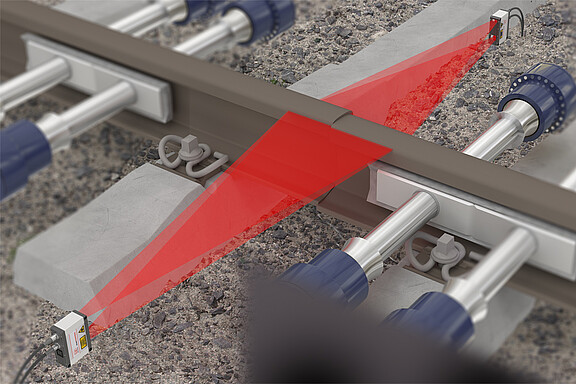

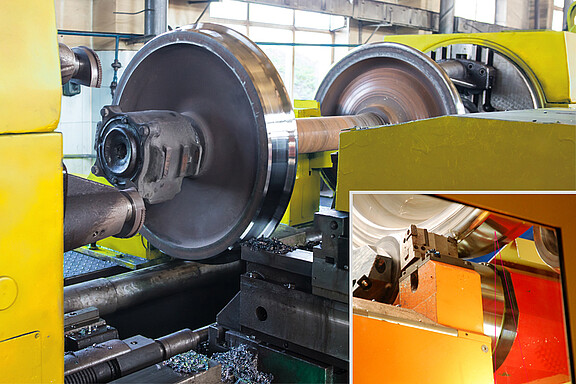

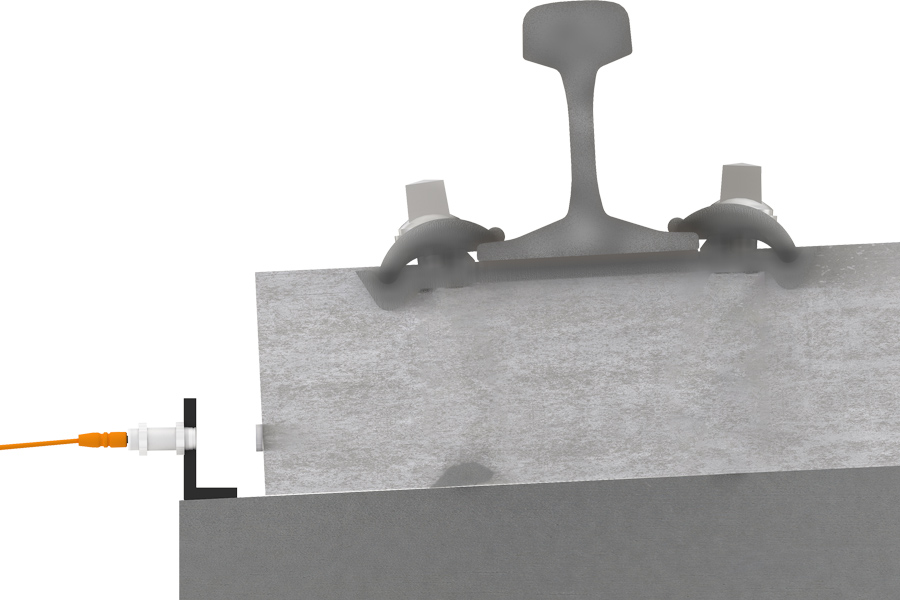

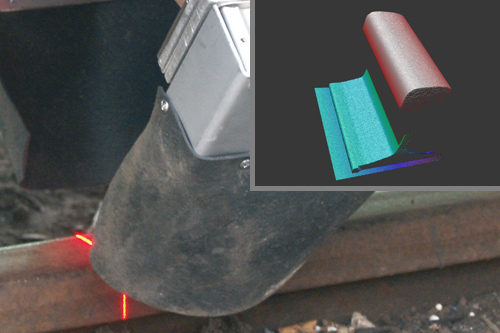

Increased utilization of rail networks and higher speeds of modern trains cause high loads on the railway vehicles and rail tracks. In order to increase operational safety in passenger and freight transport and to plan maintenance intervals in advance, inspections must be carried out on a regular basis. Therefore, Micro-Epsilon offers a wide range of precise sensors. In addition to their ease of integration, the sensors are characterized by high precision and robust designs. They are used, for example, for measurements on tracks, wheelsets and overhead lines. In addition, Micro-Epsilon offers sensors that are integrated directly into locomotives and railcars in order to monitor inclination and vibration.