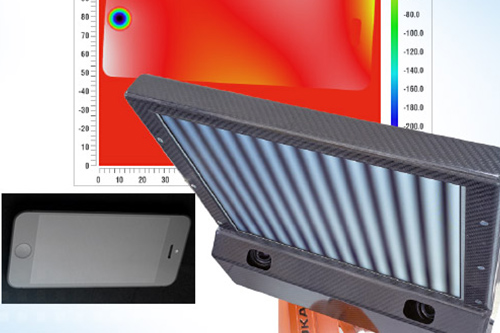

Glass production

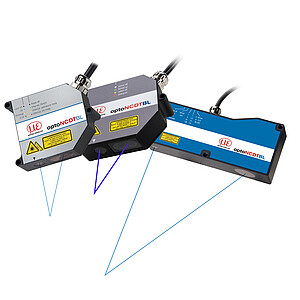

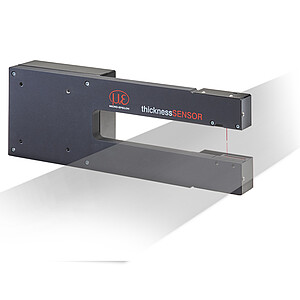

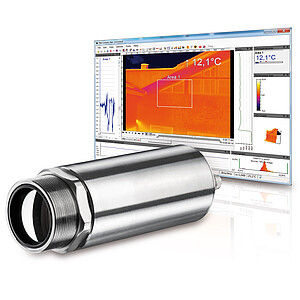

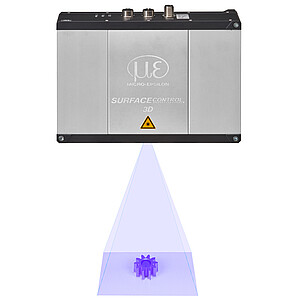

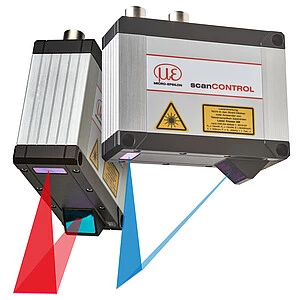

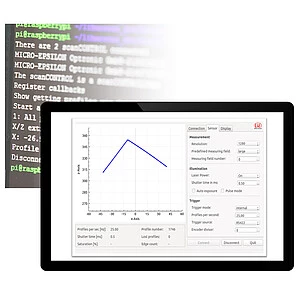

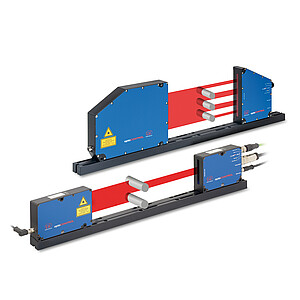

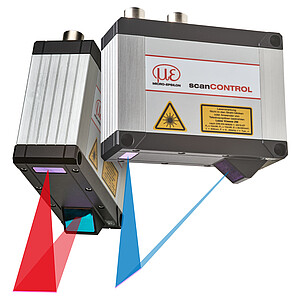

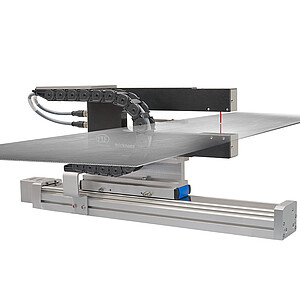

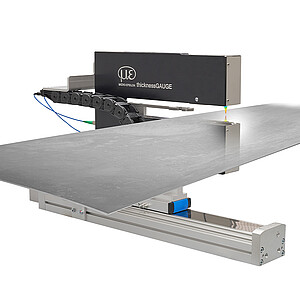

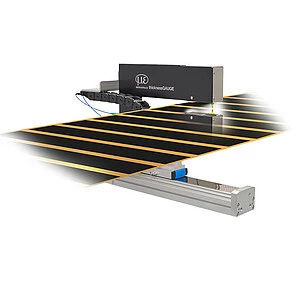

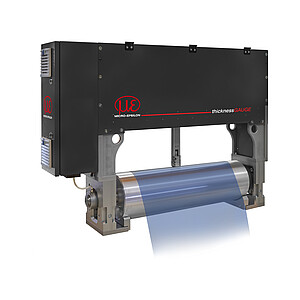

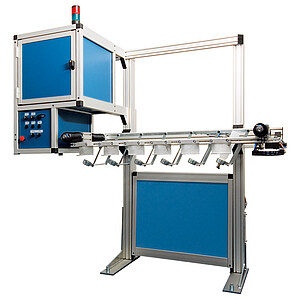

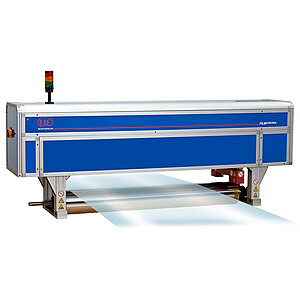

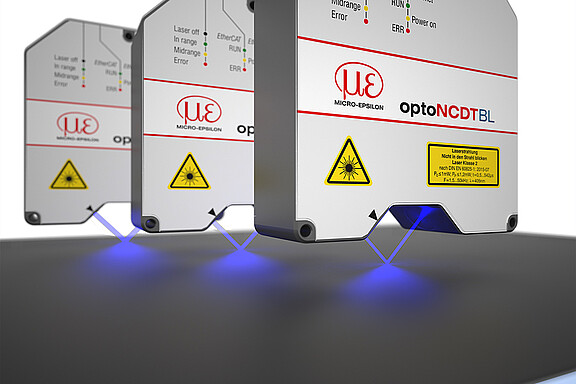

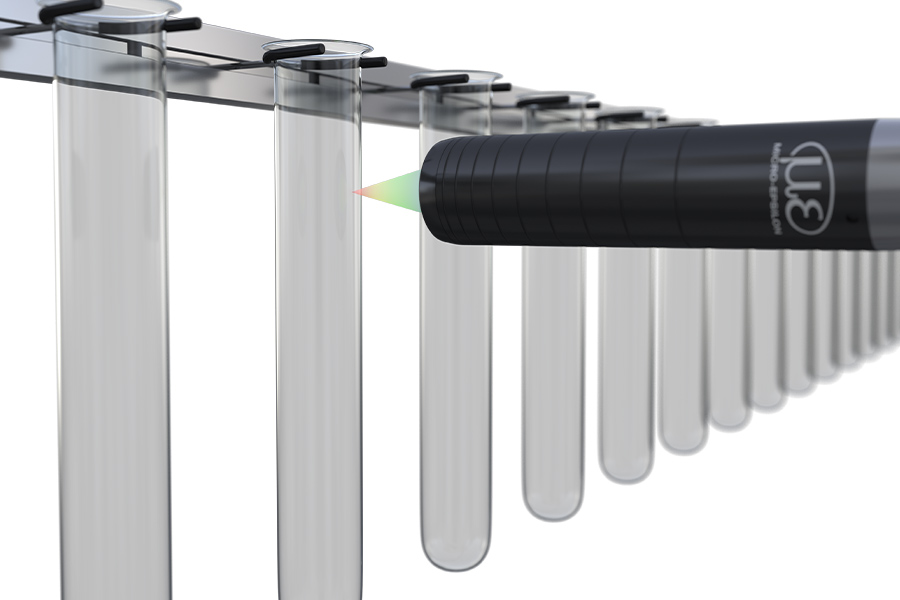

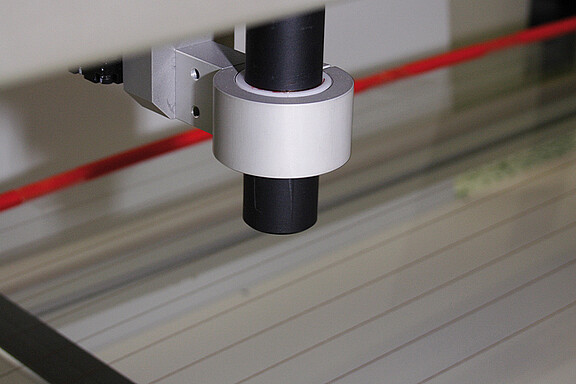

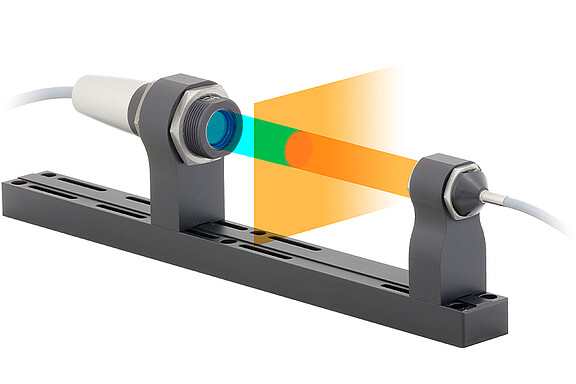

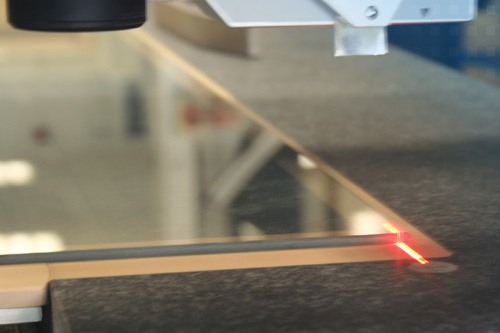

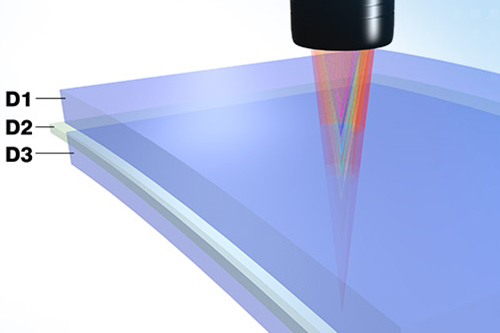

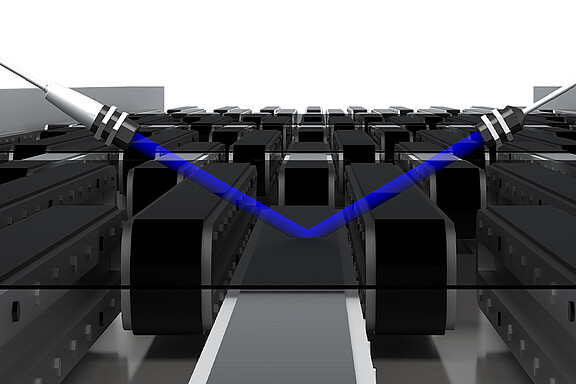

Products such as container glass, flat glass or special glasses require tight manufacturing tolerances while maintaining the shortest possible production cycles. Due to the high degree of integration as well as the high accuracy and measurement speed, sensors from Micro-Epsilon are often used in the glass industry: robust inductive sensors are integrated into machines in order to detect machine movements while optical sensors monitor the glass products in processing lines. Typical measured parameters include displacement, position, thickness, color and temperature.